Vandewiele Group @ ITMA 2023

HCE3+ Handlook weaving machine (Source: Vandewiele)

With a long history of innovation, the Vandewiele group of companies will exhibit their array of machinery at the ITMA 2023 international trade fair in Milan/Italy from June 8-14, 2023. At the exhibition, visitors will be able to see latest innovations from Vandewiele, Bonas, Cobble, Savio, Superba, Mamminger-Iro, Mesdan, Protechna Herbst and Seedo Treepoint.

All the Vandewiele machines can be connected through cloud computing to the “TEXconnect” supervision system to comply with the Factory 4.0 concept.

All the Vandewiele machines can be connected through cloud computing to the “TEXconnect” supervision system to comply with the Factory 4.0 concept.

Carpet weaving machinery

Carpet machines from Vandewiele NV, Kortrijk/Belgium, have proven to be efficient and reliable, with state-of-the-art features that assure productivity, reduced costs, and higher quality carpets. At the ITMA 2023, the company presents 3 new carpet weaving machines.

The RCF carpet weaving machine with the digital “Fast Creel”, weaving at highest speed ever, up to 250 rpm also offers flexibility for quick color changes, economical (less machine standstill and plannable creel changes) and less waste yarn.

The 3-rapier cut-loop machine USF in Fast Creel solution has possibilities of alternative weave structures and very good tension control in the loops. Carpet manufacturers are offered higher efficiency, superior production, and improved sustainability.

In the segment of Handlook weaving machines, the new generation HCE3+ is equipped with the Vandewiele U4 jacquard machines, to apply highly productive 3-rapier weave structures and to make local flatweave effects, with new possibilities in designing and writing text.

All weaving machines are characterized by “ACES”: Autonomous machines with sensors and analytical capabilities, connected machines, electrical motions instead of mechanical drives, and smart machines that apply AI instead of operators.

Jacquard technology

The Bonas brand of Vandewiele continues to build on the success of innovations in jacquard technology. Future proof digital machines with maximum weaving design flexibility are paramount. The Bonas jacquard range, with up to 31.104 hooks in a single jacquard or 62.208 hooks when coupled, is already used in the fashion, home, floor, and technical textiles markets.

Low energy consumption, even for high-speed weaving, is additionally emphasized on the Si range. The Smart Drive is equipped with a unique feed forward system, predicting the design-related load so minimizing the overall power consumption.

Clear and reliable bi-directional data communication is made possible by the fast responding, easy to use Ce controller. Preventive Maintenance and Smart Energy Management, among other features, are easily accessible. Bonas allows 100% diagnostics of the selection system. A total of 7 Bonas jacquard machines will be on display at the ITMA.

Tufting machines and ancillaries

With many years of experience, Vandewiele-Cobble continues to offer innovative tufting solutions. The machines have already proven to be reliable and cost-effective. As the company continues to innovate and offer cutting-edge solutions to meet the evolving needs of the textile industry, it will showcase its latest innovation, the High Speed Tuft (HST) machine.

The HST machine, by Vandewiele-Cobble, was designed to meet the growing demand for high-quality and high-speed production, and offers high levels of productivity and efficiency.

The machine has several advanced features, including a high-speed needle bar and servo controlled looper drive, which allows for faster and more precise tufting, and an advanced control system that ensures maximum production efficiency. The company's new technology is also environmentally friendly, as it minimizes waste and reduces energy consumption. Its advanced control system allows for precise material management, minimizing fabric waste and maximizing production efficiency.

High Speed Tuft (HST) machine (Source: Vandewiele)

Automatic windersSavio Macchine Tessili SpA, Pordenone/Italy, is launching the newest automatic winder Proxima Smartconer. The new high-tech winding machine is capable of perfectly adapting to demands of Connectivity, Industry 4.0 and Industrial Internet of Things. The design has a strong focus on the main benefits for customer’s competitive advantage: high productivity, low energy consumption, premium yarn quality, automation, and data connectivity.

The main benefits of the Proxima Smartconer are high productivity thanks to the new Smart Booster, a shorter bobbin change cycle and a faster splicing cycle, as well as low energy consumption through the usage of the latest and most efficient self-regulating independent motors and frequency inverters. Furthermore, the winding machine provides premium package quality thanks to the new splicer and new tension control. The machine is easy use thanks to the new HMI - Human Machine Interface allowing efficient bobbin flow in the automated models. Easy maintenance and accessibility to components are additional benefits.

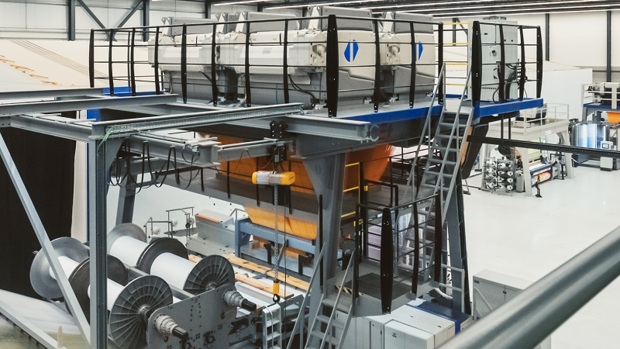

Vandewiele Extrusion

The BCF Extrusion department of Vandewiele is focusing on energy saving, easy handling and recycling.

All are combined in the latest developments:

• Redesigned spin packs to assure the fastest change in BCF Extrusion.

• Draw Frame with new developed ergonomic inlet section.

• Seco system which provides a good color separation without the need for

pre-intermingling.

• Inca system which gives superior tangle knot regularity and the highest savings towards air consumption for BCF in the market.

The machine has optimal configuration and conditions for handling recycled materials. The Extrusion department is combining efforts with top class research and industrial partners for innovative materials production in BCF.

Heat-setting, knotting, space-dyeing

Superba SAS, Mulhouse Cedex/France, already a leader in heat-setting with saturated steam under pressure thanks to their well-known TVP3, is now offering the KR1, a brand-new automatic knotting system assisted by a robot. The KR1 system can be used in many industrial branches, and enables the handling, packing and labeling of bobbins. This machine is suitable for DTY, BCF, artificial turf, tire cord, tape and more, and helps customers to improve their productivity thanks to an industrial robot running 24/7.

The MCD3(M) is an improved version of the MCD3 space-dyeing machine, a structure scalable on demand that can be set up in the right size of the dyeing machine based on customers’ production requirements with the option to add additional dyeing modules and scale the system at any time to meet growing needs. It has also been made more reliable by replacing the piezo by a brushless motor, which significantly reduces the risk of failure and, therefore, maintenance needs due to its high reliability.

Process technology for knitting machines

Memminger-Iro GmbH, Dornstetten/Germany, is a leader in the development, production and sale of yarn feeders, monitoring and lubrication systems for knitting machines. At the ITMA 2023, the company will present latest developments on a 240 m² exhibition stand.

The K52 is the latest generation of high-tech storage feeders, equipped with a CAN BUS communication and focused on functionality, easy maintenance and simple operation. Highlights are the newly developed spiral output brake for finer and even adjustment of yarn output tension, integrated yarn consumption measurement and automatic determination of the quickest possible stopping time in case of yarn breakage (“Fast stop”). K52 ATC is equipped with an Active Tension Control system, which ensures that the yarn output tension remains constant at the pre-set value, independent from external factors like size of the bobbins or quality of the yarn.

The servo motors of MRA 4 completely replaces the quality adjustment pulley assembly. This results in a constant, precise stitch length and therefore an improved fabric quality. Article reproducibility is more accurate. The technical parameters of the motors are adapted to a faster circular knitting machines with more feeders.

The Memminger-Iro Communication Interface MCI is designed to control storage feeders, tension-controlled feeders, motor drive systems and quality control devices produced by the company. This latest generation is webserver based. It is possible to operate one machine or several machines using one panel. With the MCI the knitter gets the maximum flexibility according to its demand.

The storage feeder SFE 2 is an economical version of storage feeders which includes all state-of-the-art functionalities such as adjustable yarn input tensioner, yarn separation and stepless adjustable yarn output tension.

MTD (Memminger Tech Drive) is a positive drive for flat knitting machines which enables twist-free unspooling of the material to be processed. MTD is applied in the production of different textile fabrics. It can be used for processing wire and monofilament as well as twist-free requirements for aramid, fiber, glass, etc.

Yarn splicing technology and laboratory testing equipment

Yarn knotters and splicers from Mesdan SpA, Puegnago del Garda/Italy, are produced in the automatic version (e.g. as an integral part of Savio winders) and as hand-operated units. Apart from spinning, weaving, knitting, etc., Mesdan’s yarn splicers can be found in numerous textile sectors such as the tire cord industry, sewing threads manufacturing, cable reinforcement, ropes and fishing nets, umbilical’s, medical and disposable hygiene industry, technical yarns/roving (made of fiberglass, carbon fiber, aramid), automotive, and more.

Mesdan-Lab is one of very few textile laboratory equipment suppliers offering a comprehensive range of testing equipment: for fibers, yarns, fabrics, nonwovens, garments, etc., both physical analysis as well as dyeing and finishing assessment, including color fastness testing. Mesdan-Lab also supplies standard consumables as well as calibration services.

At the ITMA 2023 Mesdan will display on the corporate Vandewiele stand in the Spinning Hall together with Savio, Loepfe and Superba, and will highlight:

• new and innovative mechatronic and electronic splicer for the new Savio winder Proxima;

• all yarn joining solutions and technologies for the different applications: knitting, weaving, sewing threads, technical textiles, etc.;

• new cotton fiber testing equipment: Contest-F2 (high volume cotton fiber testing equipment), Contest-S (cotton stickiness tester);

• new yarn and fabric testing equipment: Autofil (high speed fully automatic yarn strength tester), Autodyn 3 (tensile strength tester for fibers, yarns, hanks and fabrics), Burstmatic (pneumatic bursting tester for knitted and woven fabrics);

• new lab-scale equipment for the textile mechanical recycling: Lab Shredding Machine, complementing the well-known Mini-Spinning line, extending its applications towards textile recycling.

Being the exclusive distributor in Western Europe of Thermetrics LLC, Seattle, WA/USA, (a manufacturer of measuring equipment for the thermal and physiological comfort of fabrics and garments), Mesdan will be present also on their stand, exhibiting equipment for the technical fabric testing.

Thread and fabric control systems

Protechna Herbst GmbH & Co. KG, Neubiberg/Germany, will be present at the ITMA an 80 m² exhibition stand. Among other products, the company will present latest developments including the Cogastop Creel 2 3210 yarn monitoring system, suitable for sectional warping machines. The system can be used for the detection of slubs, double threads, knots and spinning defects. It can also transfer data via USB stick or network to connect to ERP system or MES.

The Warpstop 2 3050 yarn monitoring system is suitable for direct warping machines. This system also detects slubs, double threads, knots and spinning defects. Furthermore, it has an increased dynamic range to handle all typical yarn titers with one setup.

Suitable for warping machines, Tensoscan 2 5374 is a system for the monitoring of thread tension. The wireless design means one measuring carriage for multiple warping machines. The system provides access to the measurement data from anywhere.

Setting the operating parameters via the display of the control unit, the Laserstop Loom 2 4182 is a thread break detection system suitable for weaving machines. It has an easy to operate menu control in different user languages.

Textile dyeing and finishing automation and digitalization

Sedo Treepoint offers process, color and energy management software solutions.

Systems from the company provide many cutting-edge features for the Smart Factory which is integrated in the complete textile manufacturing process. Its products help to improve sustainability, reduce costs, and increase productivity and efficiency at the same time.

As one of its highlights, Sedo Treepoint GmbH, Mengerskirchen/Germany, presents the new Sedomat 6000/8000 textile finishing machine controller series which are designed for full digitalization and support for cloud solutions.

Smart Indigo is a new patented invention from Switzerland. The Smart Indigo machine produces Leuco-Indigo with electricity instead of chemicals, making it the most environmentally friendly method of obtaining indigo. Ecology and economy go hand in hand, as it is also far more affordable than conventional liquid indigo.

Textile dyeing and finishing solutions

The IRO-ROJ brand brings a new standard of Generation 4 yarn feeders. The new X4 Yarn feeders has “integrated accessory display” setting. The current settings and any alarms can be easily monitored using the integrated display – with any required changes being easily made using the adjustment knob.

X4 feeders are available in 3 different versions – (1) with integrated Tension

Display (TED), (2) with integrated Active Tension Control (ATC) and (3) with Quick release.

TED – Tension Display makes it possible to reproduce weft tension settings from one machine to another. This enables a fast start-up the next time the same article is woven. The position of the S-Flex Tensioner is constantly monitored by an internal sensor – even if adjustment is made during power off.

With the ATC-W Active Tension Control the required tension is easily set and monitored on the integrated display. Once set, the system constantly regulates itself ensuring consistent yarn tension during the weaving process.

The yarn tension is continuously and accurately measured by the ATC sensor unit, sending a signal to the ATC operator unit resulting in consistently stable yarn tension at the required level. Quick release gives a quick and easy way to change the brush ring or tensioner.

Furthermore, Iro is now launching its own e-commerce platform – iroonline.com – a digital tool for ordering the range of textile accessories.

Developments in shearing and singeing

For carpets, Bejimac SA, Huldange/Luxembourg side, will present the ATSH, the new autonomous shearing machine. This machine is a newly developed technology, reducing customers’ dependency on qualified operators. Moreover, new developments for carpet back coating focused on speed, digitization, and energy savings will be presented. Information on developments in towels shearing will also be provided.

In singeing, a completely new singeing machine for knitwear was developed together with the knitwear finishing expert Erbatech GmbH, Erbach/Germany, focusing on high quality levels of singeing, operational flexibility, and economy, as well as tension-free fabric transport through the machine.

With respect to woven fabrics, the new developments made to substantially reduce the gas consumption while offering high intensity singeing will be presented.

Overedging machines

The Titan brand has developed a completely new line of compact and fast overedging machines. The Titan 4510CHC makes it possible to sew up to 18 mm thick carpets at high speed with stitch of 10 mm wide. Moreover, the company has also developed the Titan 4510AHC for sewing heavy complex shaped carpets such as aviation carpets, or flower or other shaped carpets. The Titan 4510CHX version sews 4 mm ultra-fine stitch on thick carpets.

The Titan 3700C is a carpet binding machine, which allows for a fast and industrial finishing of carpet with all kinds of ribbons and tapes from 22-150 mm.

In the same line there is also a Titan 4510CHE, the heavy duty buttseamer sewing machine to sew together the end of one roll to the beginning of the next roll for heavy qualities such as artificial grass or other carpets before the backsizing process.

Finally, the latest generation of fully digital carpet robot will be shown. The Titan 5540 is able to sew fully automatically car mats and doormats up to 100 x 160 cm large with complex shapes. No programing of the shape is necessary, and the carpets are stacked and ready for packing and shipping. One operator can manage to run 4 of these robots.

Smartconer, Mesdan = registered trademarks

Smart Indigo = trademark