Toray

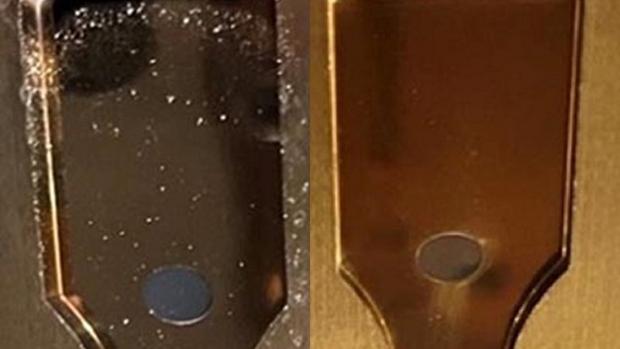

White silicone spots on injection mold surface before (left) and after (right) improvement (Source: Toray)

Achieving the same flowability and mechanical properties as injection molding grades from virgin polyamide 66 (PA 66), Toray has developed recycled PA 66 recovered from silicone-coated airbag fabric scrap cuttings. The company created this product by combining particular additives with resin that Refinverse recycled by stripping silicone from airbag fabric scrap cuttings and thereafter washed.

Toray Industries, Inc., Tokyo/Japan, expects the new offering, Ecouse Amilan, will accelerate the expansion of Ecouse, a proprietary integrated brand for eco-friendly recycled materials and products that it rolled out worldwide in 2015.

The PA 66 fabric of airbags can be silicone-coated or non-coated. Manufacturers normally recycle the scrap cuttings of non-coated fabrics. Recycling coated airbag fabric scrap cuttings requires removing the silicone. Refinverse Group, Inc., Tokyo/Japan, was the first in Japan to achieve commercial-scale silicone-coated fabric recycling.

Recycling through stripping and washing has typically left silicone traces, however, degrading the resin and contaminating molds during injection molding. Another issue has been that the high viscosity of airbag yarn limits applications in thin-wall and other injection molding processes in which high fluidity is vital. Toray accordingly combined particular additives so residual silicone resin would not migrate to the surface of molded products. It also greatly reduced mold adhesion. That is why the flowability and mechanical properties of recycled PA 66 with Toray’s technique are equal to those of virgin PA 66.

The company has cultivated recycled plastic products derived primarily from post-industrial scrap materials from in-house production processes, undertaking such efforts as recycling used air conditioner parts into new ones. It aims to extend recycling to used automotive parts and industrial equipment.

Toray intends to launch Ecouse Toraycon as a chemically recycled polybutylene terephthalate (PBT) resin product that has properties equivalent to virgin materials. It will keep assessing material recycling and chemical recycling for its own polymers in driving to expand the Ecouse lineup by bringing out such products as Ecouse Toyolac acrylonitrile butadiene styrene, Ecouse Torelina polyphenylene sulfide.

Toray Industries, Inc., Tokyo/Japan, expects the new offering, Ecouse Amilan, will accelerate the expansion of Ecouse, a proprietary integrated brand for eco-friendly recycled materials and products that it rolled out worldwide in 2015.

The PA 66 fabric of airbags can be silicone-coated or non-coated. Manufacturers normally recycle the scrap cuttings of non-coated fabrics. Recycling coated airbag fabric scrap cuttings requires removing the silicone. Refinverse Group, Inc., Tokyo/Japan, was the first in Japan to achieve commercial-scale silicone-coated fabric recycling.

Recycling through stripping and washing has typically left silicone traces, however, degrading the resin and contaminating molds during injection molding. Another issue has been that the high viscosity of airbag yarn limits applications in thin-wall and other injection molding processes in which high fluidity is vital. Toray accordingly combined particular additives so residual silicone resin would not migrate to the surface of molded products. It also greatly reduced mold adhesion. That is why the flowability and mechanical properties of recycled PA 66 with Toray’s technique are equal to those of virgin PA 66.

The company has cultivated recycled plastic products derived primarily from post-industrial scrap materials from in-house production processes, undertaking such efforts as recycling used air conditioner parts into new ones. It aims to extend recycling to used automotive parts and industrial equipment.

Toray intends to launch Ecouse Toraycon as a chemically recycled polybutylene terephthalate (PBT) resin product that has properties equivalent to virgin materials. It will keep assessing material recycling and chemical recycling for its own polymers in driving to expand the Ecouse lineup by bringing out such products as Ecouse Toyolac acrylonitrile butadiene styrene, Ecouse Torelina polyphenylene sulfide.

Amilan, Toraycon, Toyolac, Torelina = trademarks