STFI @ Index23

(Source: STFI)

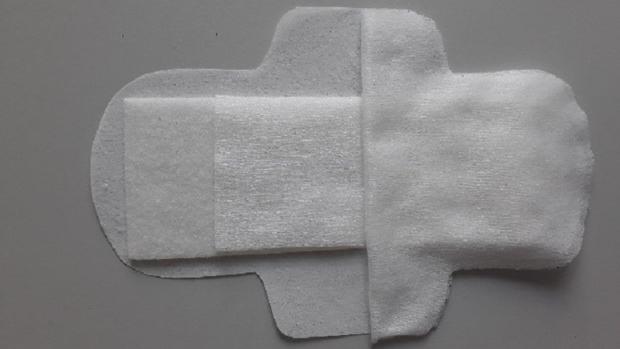

The Saxon Textile Research Institute e.V. (STFI), Chemnitz/Germany, will present news from its nonwovens research, among other things the bio-based hygiene nonwoven BioHyg. The starting point for the innovation was the search for a washable and thus reusable absorbent pad made from completely bio-based materials for applications in baby, feminine and incontinence hygiene. The focus was on 2 main requirements: fast and efficient liquid distribution and high absorbency to minimize rewetting and leakage. To ensure this, an innovative nonwoven construction was developed, that closes the technological gap between sufficient dimensional stability and as little fiber dam-age as possible due to the bonding mechanisms. The developed nonwovens layers can be used as a stand-alone solution as a single-use product with bio-based materials or integrated into a washable composite structure.

Furthermore, the STFI will be showing innovations in the recy-cling of high-performance fibers. On display will be a battery housing developed jointly with the research partner Fraunhofer ICT, Pfinztal/Germany. Detailed investigations into the use of recycled carbon fibers in the SMC process chain were carried out at the Institute. To this end, nonwovens were first developed that enable the recycled carbon fibers to be fed into the SMC plant. The SMC semi-finished products could then be processed by both molding and impact extrusion. Comparison with conventional SMC products showed that comparable characteristic values could be achieved with a lower fiber volume content. Developments in the field of renewable raw materials in combination with bio-based resin systems also offer forward-looking materials.

A third research project aimed on developing an improved pipe liner system for trenchless pipe rehabilitation. In particular, the force absorption in the longitudinal direction and the flexibility without wrinkling were improved and the use of material as well as the pore volume of the textiles were optimized for the best possible impregnation with resin. The project included nonwoven development, coating of the liners and the use of UV-curable resins for curing. At the Index, the STFI will present a demonstrator showing a nonwoven-based pipe liner with coating, which in turn was impregnated with a UV-curable resin and cured using UV LED lamps.

Furthermore, the STFI will be showing innovations in the recy-cling of high-performance fibers. On display will be a battery housing developed jointly with the research partner Fraunhofer ICT, Pfinztal/Germany. Detailed investigations into the use of recycled carbon fibers in the SMC process chain were carried out at the Institute. To this end, nonwovens were first developed that enable the recycled carbon fibers to be fed into the SMC plant. The SMC semi-finished products could then be processed by both molding and impact extrusion. Comparison with conventional SMC products showed that comparable characteristic values could be achieved with a lower fiber volume content. Developments in the field of renewable raw materials in combination with bio-based resin systems also offer forward-looking materials.

A third research project aimed on developing an improved pipe liner system for trenchless pipe rehabilitation. In particular, the force absorption in the longitudinal direction and the flexibility without wrinkling were improved and the use of material as well as the pore volume of the textiles were optimized for the best possible impregnation with resin. The project included nonwoven development, coating of the liners and the use of UV-curable resins for curing. At the Index, the STFI will present a demonstrator showing a nonwoven-based pipe liner with coating, which in turn was impregnated with a UV-curable resin and cured using UV LED lamps.