Retech @ ITMA 2023

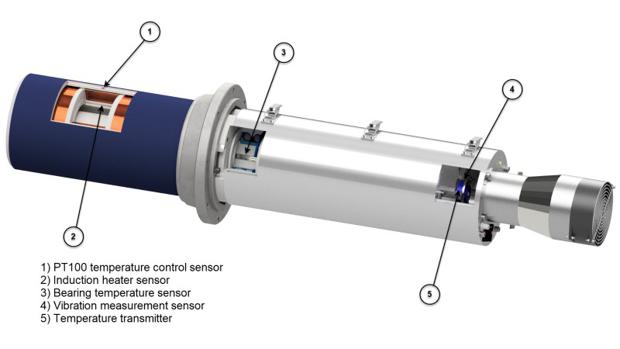

IoTs in a modern heated godet (Source: Retech)

Godet rolls are essential components in the production of synthetic fibers. These heated, ambient or cooled rolls help achieve the perfect yarn quality for a range of materials and applications when it comes to heat treatment for filament fiber applications. The godet rolls by the supplier of components and machinery for man-made fiber production Retech AG, Meisterschwanden/Switzerland, provide unique designs that allow for greater control over temperature, fiber treatment and sustainability. In addition, the company also focuses on energy efficiency when it comes to motors and heating equipment. This means all Retech products use less energy than traditional systems, making them more cost effective over time while achieving very good results. Retech’s heated godet rolls are designed with 2 requirements in mind: applying exactly the correct temperature for the material being produced; and maintaining this level continuously throughout the process. To do this, their designs incorporate energy saving technology, using single-zone or multi-zone heating using induction, infrared or resistance. This ensures accuracy and precision when it comes to surface temperature profiles.

Furthermore, a very important part of the godet concept is the long service life and the associated permanent availability, thus reducing machine downtimes and the production of rejects. If a godet fails, there is immediately a great loss, inconvenience and disruption to the production process. Therefore, Retech has equipped its godets with additional measuring elements in order to be able to react preventively to possible damage and subsequent failure. Thanks to the temperature measuring transmission system UTR-6A, which measures the temperatures in the rotating godet and transmits the data to the temperature controller UCR-6 for processing without contact, it is possible to take further measurements, collect data and evaluate them. To protect the godet, the ongoing production and ultimately the sustainability of the entire process and the godet itself.

Furthermore, a very important part of the godet concept is the long service life and the associated permanent availability, thus reducing machine downtimes and the production of rejects. If a godet fails, there is immediately a great loss, inconvenience and disruption to the production process. Therefore, Retech has equipped its godets with additional measuring elements in order to be able to react preventively to possible damage and subsequent failure. Thanks to the temperature measuring transmission system UTR-6A, which measures the temperatures in the rotating godet and transmits the data to the temperature controller UCR-6 for processing without contact, it is possible to take further measurements, collect data and evaluate them. To protect the godet, the ongoing production and ultimately the sustainability of the entire process and the godet itself.