Mimaki

(Source: Mimaki)

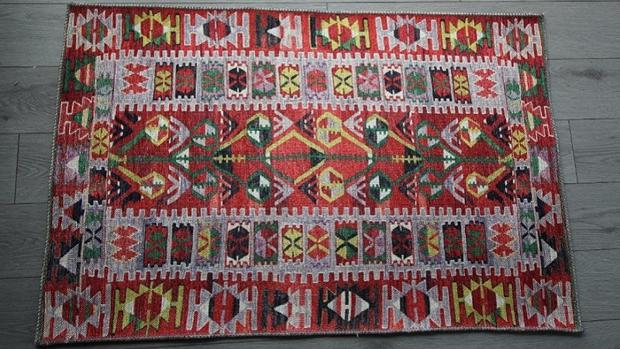

The consumption habits of society have changed. Previous generations used to buy thick woven carpets and use them for 20-30 years, as an insulating material in homes. However, due to the widespread urbanization and natural gas infrastructure, the need for carpets to insulate the home has disappeared. We are now in a period of faster consumption, and low prices have increased the interest in these products, alongside them being much easier to maintain. The carpet now stands as a decorative element in homes and living spaces, to be changed seasonally or to match with the interior design.

The manufacturer of digitally printed carpets, Makroser, has been utilizing Mimaki’s high-performance TS300P-1800 sublimation transfer printer since 2020. The company has optimized their production potential to meet increasing customer expectations in the growing digital textile carpet market.

Makroser Tekstil, Istanbul/Turkey, serves as a raw material supplier in the supply chain, a manufacturer of carpets and home textiles and carries out studies for the development of the digital printed carpet industry.

The company invested in a Mimaki TS300P-1800 sublimation transfer printer in August 2020 and with it gained a good competitive advantage in the digital printed carpet business. Makroser has an approximate monthly output of 150,000 m² of final product and sells about 70-80,000 m² of intermediate goods per month. Digitally printed carpets have succeeded in getting ahead of woven carpets with their ease of use, low cost, and plenty of color and pattern options.

The TS300P-1800 sublimation transfer printer from Mimaki Europe, Amsterdam/Netherlands, using core technologies allows for uninterrupted printing and has made managing multiple printers with a single operator and computer simpler, saving both time and money. Quality and consistency of the colors and patterns remains stable indefinitely.

In addition to the printer itself, Makroser uses original Mimaki ink in the printer, which has helped the company optimize its ink consumption. While it is necessary to use 4 ml to print 1 m² of paper with a similar ink, the same can easily be done with 2 ml of Mimaki ink. Ink consumption has been reduced by 30%, all while maintaining the print quality. As well as saving on cost, Mimaki’s inks are certified to be harmless to human health and environmentally friendly.

The manufacturer of digitally printed carpets, Makroser, has been utilizing Mimaki’s high-performance TS300P-1800 sublimation transfer printer since 2020. The company has optimized their production potential to meet increasing customer expectations in the growing digital textile carpet market.

Makroser Tekstil, Istanbul/Turkey, serves as a raw material supplier in the supply chain, a manufacturer of carpets and home textiles and carries out studies for the development of the digital printed carpet industry.

The company invested in a Mimaki TS300P-1800 sublimation transfer printer in August 2020 and with it gained a good competitive advantage in the digital printed carpet business. Makroser has an approximate monthly output of 150,000 m² of final product and sells about 70-80,000 m² of intermediate goods per month. Digitally printed carpets have succeeded in getting ahead of woven carpets with their ease of use, low cost, and plenty of color and pattern options.

The TS300P-1800 sublimation transfer printer from Mimaki Europe, Amsterdam/Netherlands, using core technologies allows for uninterrupted printing and has made managing multiple printers with a single operator and computer simpler, saving both time and money. Quality and consistency of the colors and patterns remains stable indefinitely.

In addition to the printer itself, Makroser uses original Mimaki ink in the printer, which has helped the company optimize its ink consumption. While it is necessary to use 4 ml to print 1 m² of paper with a similar ink, the same can easily be done with 2 ml of Mimaki ink. Ink consumption has been reduced by 30%, all while maintaining the print quality. As well as saving on cost, Mimaki’s inks are certified to be harmless to human health and environmentally friendly.