Tailorlux

(Source: Tailorlux)

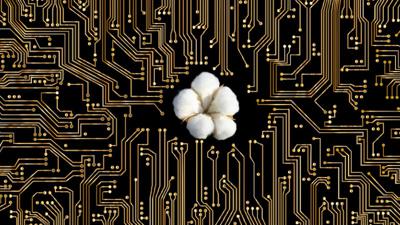

In May 2022 the Spanish companies Retexcycle, Barcelona, Eurosemillas SA, Córdoba, Surcotton SA, Córdoba, Eurofins Analytico BV, Barcelona, and Tailorlux GmbH, Münster/Germany, started a common traceability project from seed to garment. This project was designed to show what is possible in cotton traceability and underline the advantage of Spanish cotton.

Brands and retail are intrigued, and European cotton has a satisfactory selling proposition. The objective is to show how a digital twin, a third-party verification and a physical tag can be combined to address specific sourcing risks of cotton. The companies want to show how traceability can work.

Key elements of this project are:

- The creation of digital twins in different steps of the supply chain with the Retexcycle software.

- The third-party verification of GMO-free seeds by Eurofins.

- The automated and exact dosing of tracer fibers in the ginning facilities of Surcotton to implement the “Optical Fingerprint” of the Tailorlux integriTex solution.

- The transfer of marked integriTEX bails to Tejidos Royo with digital transaction certificates.

Key elements of this project are:

- The creation of digital twins in different steps of the supply chain with the Retexcycle software.

- The third-party verification of GMO-free seeds by Eurofins.

- The automated and exact dosing of tracer fibers in the ginning facilities of Surcotton to implement the “Optical Fingerprint” of the Tailorlux integriTex solution.

- The transfer of marked integriTEX bails to Tejidos Royo with digital transaction certificates.

In May 2022, Eurosemillas seed was verified as GMO-free by Eurofins, a global player in verification services. Hence it was possible to grow cotton that addresses several sourcing risks by being grown under the European labor laws, GMO-free and part of a nearshoring concept to manufacture yarn, fabrics, and garments in Spain. The start was marked by creating digital twins of each seed bag.

All the farmers using the system received a mobile application to scan the unique ID of each bag to link it to a specific cotton field of the official Spanish cadaster.

The result is shown in a map of traceable cotton fields. The harvest began in October and new “birth certificates“ have been created by the delivery of cotton to the ginning facilities of Surcotton. Trucks arrive at the facility and weighting sheets and field locations go into the Retexcycle system. The cotton is now ready for ginning and for adding a tracer fiber that carries the “Optical Fingerprint” for Andalusian cotton. This tracer fiber is added in a ratio of 1:1,000 to the ginning process. It is a special expertise to dose such small quantities. Tailorlux presented the newly designed fiber dosing machine (Fig.) that can be installed within 2 hours in any gin or spinning facility. This makes this concept scalable in every region of the world. The machine has to keep up with the flow rate of the gin and sustain harsh conditions.

Fiber dosing machine (Source: Tailorlux)

The exact dosing of tracer fibers is the key element for detection of the dilution of cotton in yarn, fabrics and garments. Tailorlux is currently working on a dilution verification process with Eurofins to offer worldwide services in tracer detection and quantification. All bales that left the gin are now machine-readable and can be identified with the Tailorlux handheld sensors.

Each bale then creates a new item on the Retexcycle system to be allocated to different transaction certificates.

The entire batch was purchased from Tejidos Royo, which is the leading company in this innovative project. At Tejidos Royo, all bales are converted into scannable yarns and fabrics. These will then be sold to well-known brands that will benefit from the advantages of Spanish cotton.

The combination of all the technologies enables fashion brands to prove the origin of the cotton along the entire value chain. B2C customers of these brands will be able to trace the journey of the materials from seed to finished garment. This helps fashion brands to comply with French and German supply chain laws and prevent greenwashing and resource waste.

integriTEX = registered trademark

What is a digital twin?

A digital twin will be created for each item that has been produced during the value chain. It is a unique identifier that can be expressed, e.g. in data matrix or QR codes. Each of these twins create a “birth certificate”, an item that only can be transferred once by allocating it to a digital transaction certification on a distributed ledger (non-public blockchain).

A digital twin will be created for each item that has been produced during the value chain. It is a unique identifier that can be expressed, e.g. in data matrix or QR codes. Each of these twins create a “birth certificate”, an item that only can be transferred once by allocating it to a digital transaction certification on a distributed ledger (non-public blockchain).

This article was published in melliand International 6/2022