Interview with Carolina Sister Cohn, Eastman

Carolina Sister Cohn (Source: Eastman)

One of the most pressing issues in apparel industry is developing large-scale circularity. The new cellulosic fiber Naia Renew meets these sustainability demands. Produced from 60% sustainably sourced wood pulp and 40% certified recycled waste material, Naia Renew creates value from hard-to-recycle content that would otherwise be destined for landfills.

What kind of waste is used? Pre- or post-consumer waste? How is the performance of these fibers?

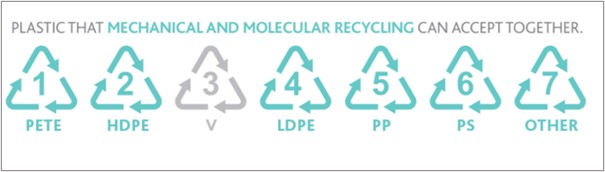

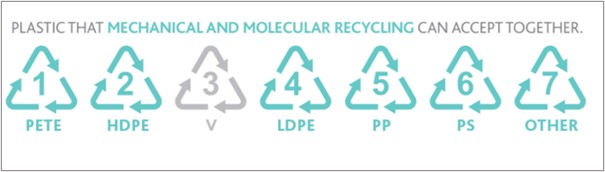

Our carbon renewal technology enables us to recycle various waste materials that have previously been very difficult to recycle using traditional mechanical techniques, such as post-consumer carpet fiber and other postindustrial plastic packaging materials.

This molecular recycling technology breaks down waste into its molecular building blocks so it can be reused over and over again – creating an infinite life span for materials that were previously destined for landfill.

Our carbon renewal technology enables us to recycle various waste materials that have previously been very difficult to recycle using traditional mechanical techniques, such as post-consumer carpet fiber and other postindustrial plastic packaging materials.

This molecular recycling technology breaks down waste into its molecular building blocks so it can be reused over and over again – creating an infinite life span for materials that were previously destined for landfill.

(Source: Eastman)

Since we are recycling at molecular level, the resulting fiber is chemically identical to classic Naia, retaining its same properties and quality. How can the quantities of recycled fibers be increased? What are the biggest challenges for the recycling of fibers?

I believe brands and consumers are gaining more and more knowledge about circularity, and demand for circular products is increasing. The biggest challenge remains manufacturing capacity. Naia Renew is one of the few products in the market that is produced at scale, and we will continue to invest in capacity expansion over the next years.

Another common challenge with other types of fibers is also that the outcome of recycled fibers is not as high-performing as the virgin equivalent – this does not happen with Naia, which thanks to its molecular recycling process allows for recreating the exact same quality and properties as its virgin materials.

Are there currently sufficient quantities of used textiles as a raw material for this fiber production?

Yes, currently we use post-consumer carpets to make Naia Renew.

It’s worth pointing out that textiles are not the only source of recycling materials for us: as mentioned, we also use other post-industrial plastic packaging materials, which would usually be destined for landfill as they are considered very difficult to recycle using traditional mechanical techniques.

What is the annual production capacity of this fiber? And what is the further development?

What we can say is that we are fully committed to a continuous growth and we are investing in circularity more and more: we have just announced the construction of a new plant in France only for molecular recycling items.

Circular economy at Eastman? Is there some kind of timetable for when and how your fiber production will become completely circular?

Yes, we have planned our way ahead in our Naia Sustainability Goals: by 2025, more than 50% of the textile's portfolio is going to be Naia Renew, and by 2030, more than 90.

How do you see the role of the industry here, and what is the role of the consumer?

The industry as a whole has luckily become much more aware of the responsibility we all have to reduce fashion’s impact and of how every step of the supply chain makes a difference in the journey towards circularity and sustainability. We need to work all together to be able to implement change, and we think that with Naia as a true accelerator of circularity in fashion, with transparency and scale we can change the industry!

When it comes to consumers, it is important for us as industry to explain transparently and to raise awareness on the fact that choosing low impact fibers and processes such as Naia truly matters. It is just as essential that consumers educate themselves to better understand what they are buying. Check fibers content in the garments, make sure they understand the footprint of that fiber. Look more and more for circular or recycled fibers in apparel garments.

Naia = trademark

The interview was conducted by the TextileTechnology team with Carolina Sister Cohn, Global Marketing Leader for Textiles, Eastman Chemical Co., Kingsport, TN/USA.