DITF

DITF pavilion (Source: BioMat at ITKE/ University of Stuttgart)

At this year's Architecture Biennale in Venice/Italy, the focus will be on bio-composites. A sustainable material for support profiles and connecting nodes developed by the German Institutes for Textile and Fiber Research Denkendorf (DITF), Denkendorf/Germany, is being exhibited in the Palazzo Mora during the Biennale from May 20 - November 26, 2023. The ultralight components are the result of a joint project between partners from research and industry, funded by the German Federal Ministry of Food and Agriculture, Bonn. In the future, they will be used in the field of mobile architecture and in pavilions and architecture with low load-bearing capacity.

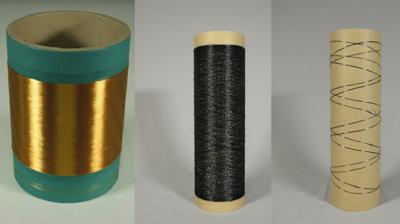

The DITF had the task of selecting suitable materials for the bio-composite and developing manufacturing processes. In order to achieve the highest possible organic content, hemp and flax fibers and a resin system based on epoxidized linseed oil were used. These natural resources were used in both pultrusion and hot-pressing processes.

Processing natural fibers into high-performance products is challenging because they are thicker, more uneven, wetter and also more sensitive than high-performance fibers made of glass, carbon or aramid. To date, natural fibers have been predominantly pultruded using petroleum-based resins or resins with a very low bio-content. The resulting composites did not achieve sufficient fiber-matrix adhesion, which is why the mechanical properties were unsatisfactory. At the DITF, these material- and process-related problems were largely solved. For example, the pre-drying of the natural fiber rovings in pultrusion was a decisive solution. What was successful on a laboratory scale at the DITF could also be implemented on an industrial scale. For the LightPro Shell Pavilion, the Buckyball and for the Biennale exhibition, project partner CG-Tec GmbH, Spalt/Germany, produced a total of 800 m of tubular profile, which was used as a support element. For the node connecting the support profiles, the project partners created a design, based on which a suitable molding tool for the hot-pressing process was produced. At the end of the project, more than 60 connecting nodes for the Buckyball were produced at the DITF using this molding tool, a section of which can now be viewed in Venice.

The DITF had the task of selecting suitable materials for the bio-composite and developing manufacturing processes. In order to achieve the highest possible organic content, hemp and flax fibers and a resin system based on epoxidized linseed oil were used. These natural resources were used in both pultrusion and hot-pressing processes.

Processing natural fibers into high-performance products is challenging because they are thicker, more uneven, wetter and also more sensitive than high-performance fibers made of glass, carbon or aramid. To date, natural fibers have been predominantly pultruded using petroleum-based resins or resins with a very low bio-content. The resulting composites did not achieve sufficient fiber-matrix adhesion, which is why the mechanical properties were unsatisfactory. At the DITF, these material- and process-related problems were largely solved. For example, the pre-drying of the natural fiber rovings in pultrusion was a decisive solution. What was successful on a laboratory scale at the DITF could also be implemented on an industrial scale. For the LightPro Shell Pavilion, the Buckyball and for the Biennale exhibition, project partner CG-Tec GmbH, Spalt/Germany, produced a total of 800 m of tubular profile, which was used as a support element. For the node connecting the support profiles, the project partners created a design, based on which a suitable molding tool for the hot-pressing process was produced. At the end of the project, more than 60 connecting nodes for the Buckyball were produced at the DITF using this molding tool, a section of which can now be viewed in Venice.