Biotexfuture

(Source: Biotexfuture)

How can we scale up sustainable (bio-based) textiles recycling? To find an answer to this question, Biotexfuture brought together Soex and I:Collect GmbH (Germany), Infinited Fiber Company Oy (IFC) (Finland), Wuppertal Institut für Klima, Umwelt, Energie gGmbH (Germany), adelphi (Germany), FullCycle (USA), IKEA (Sweden), the German Environment Agency - Umweltbundesamt (UBA) and the RWTH Aachen (Germany) at the Biotexfuture Fall 2022 Forum in October 2022.

Scaling up textiles recycling

Climate change, textile waste and plastic pollution are just some of the negative environmental impacts that have driven policy makers to create new regulations to push measures like recycling and make the textile industry more sustainable. Transforming this series of regulations like the Extended Producer Responsibility (EPR) or Digital Product Passport (DPP) into national legislation is in full swing. The deadline for practical implementation in industry is 2030. This puts companies under increasing pressure to prepare themselves not only to stay compliant, but also to stay competitive.

Climate change, textile waste and plastic pollution are just some of the negative environmental impacts that have driven policy makers to create new regulations to push measures like recycling and make the textile industry more sustainable. Transforming this series of regulations like the Extended Producer Responsibility (EPR) or Digital Product Passport (DPP) into national legislation is in full swing. The deadline for practical implementation in industry is 2030. This puts companies under increasing pressure to prepare themselves not only to stay compliant, but also to stay competitive.

Collaborating across stakeholder groups and national borders

Driving such a systemic change requires more than a few players becoming active. Crucial in this context is a multi-stakeholder collaborative process. This goes beyond national borders. The importance of collaboration on all geographic levels giving practical examples like private-public-partnerships (PPPs) was emphasized. In this spirit, a holistic way of thinking will be necessary to foster collaboration across global, national, regional, and local actors. From a partnership perspective, value chain and ecosystem collaboration, eco-design leveraging new technologies and a data driven business case will enable scaling. Furthermore, business models have to transition towards circularity.

Understanding circularity as loops within a loop

For recycling partnerships to be integrated in a circular textile economy a clear and shared definition of the latter is still needed. This is particularly relevant as the misconception of recycling being similar to or even the same as circularity still persists. Recycling is just one of the many loops within the big loop of a circular textile economy. Other loops include repurpose, remanufacture, retro logistics, reuse, redistribute, repair, rent, refuse, reduce, and share. Some of them can be used at multiple points in the value chain. Yet, the quantity and variety of loops does not diminish the importance of textiles recycling. This is especially of interest for actors involved in the production, collection, and sorting of textiles as well as brands and retailers. They will be the ones directly affected by the EPR, Ban on Destruction of Unsold Textiles, Green Claims, Ecodesign Requirements and the DPP all of which address or include textiles recycling to some extent.

Building a complementing recycling infrastructure

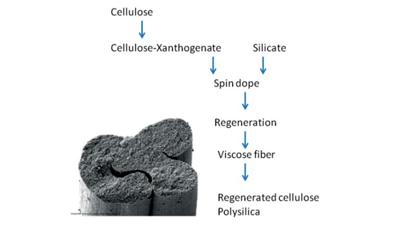

There are many methods to recycle textiles including biological, chemical, and mechanical recycling. All of these methods are at various stages of development. Mechanical recyclers for example are currently working on material recognition technologies, which are vital to simplify the recycling process. Methods, however, do not only vary with regards to their technological developments, but also with regards to their respective footprints (carbon, water, etc.). Partly it is already scientifically confirmed that some recycling methods have a lower environmental footprint than producing new products with virgin material. The more these methods and the related technologies mature, the more research will deliver insights on environmental impacts from life cycle assessments (LCAs) and environmental impact assessments (EIAs). This will enable the textile industry to combine methods to build an infrastructure with a lower negative environmental impact. To make this work, it is, nonetheless, pivotal to see these different methods, like chemical and mechanical recycling, as complementing to and not competing with each other.

Jointly investing in emissions-reducing recycling solutions

Building this infrastructure will need additional financial resources. Investors are increasingly motivated to invest in start-ups, which are profitable, but which can additionally show how their recycling activities contribute to reducing greenhouse gas emissions. For start-ups in Europe and North America this is even easier as they can take advantage of old textile infrastructure, which only needs to be revitalized. This would save transport emissions and by that score with investors. But again, to scale it will not be enough to only rely on private equity firms for investments. Industry will need to meet these recycling start-ups in the middle and invest as well.

Harmonizing legislation and experimenting with recycling solutions

But not only industry needs to accommodate startups, it is also the national policymakers’ turn to come industry’s way. Brands and companies working on textiles are still facing the challenge of vastly different recycling requirements in various countries. As this adds additional complexity to the implementation of recycling solutions, policymakers need to harmonize legislation across borders. This, in turn, should then enable actors from different EU countries to cooperate and experiment with recycling solutions across borders. However, there is still a lack of opportunities to experiment in this context.

Whether it is policymakers, who created new regulations, or brands and start-ups that began to rethink material resources, production methods, pricing and eventually business models, most actors involved have started their journey to scale up sustainable (bio-based) textiles recycling. However, this is only the start of the trip. As could be seen at the Biotexfuture Fall 2022 Forum, there are still a series of leverage points where solutions can and need to be implemented. Conceptually, circularity and recycling still need to be understood and properly differentiated. Furthermore, legislation needs to be harmonized and experimentation with recycling solutions needs to be encouraged. In parallel, investments need to be made jointly and in emissions-reducing recycling solutions, while setting up the recycling infrastructure in a complementing manner. All of this can only work effectively when collaboration across stakeholder groups and national borders is fostered.

Biotexfuture is one of 4 innovation programs supported by the Federal Ministry of Education and Research (BMBF), Berlin/Germany, as part of the "National Research Strategy Bioeconomy 2030". This program was created as part of the "Bioeconomy Innovation Spaces" funding measure and has a total duration of 5 years. The vision of Biotexfuture is the conversion of the textile value chain from petroleum-based to bio-based.

Currently, more than 73% of all fibers for the production of textile products are petroleum-based. In addition, the textile and apparel industry produces an enormous volume of plastic, of which only 9% is based on renewable raw materials to date. With Biotexfuture, players from research and industry are joining forces to promote the use of bio-based raw materials in the textile industry. The program is intended to facilitate a change of direction in this regard and promote a step towards sustainability.

Currently, more than 73% of all fibers for the production of textile products are petroleum-based. In addition, the textile and apparel industry produces an enormous volume of plastic, of which only 9% is based on renewable raw materials to date. With Biotexfuture, players from research and industry are joining forces to promote the use of bio-based raw materials in the textile industry. The program is intended to facilitate a change of direction in this regard and promote a step towards sustainability.