AVK

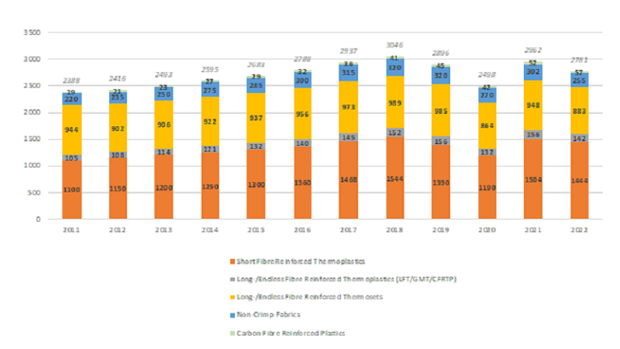

Composites production volume in Europe since 2011 (in 000 tons) (Source: AVK)

Like all industries, the composite industry has been affected by strong negative forces in recent years. Like many sectors of the economy, the industry was hit particularly hard during the Covid-19 pandemic. The war in Ukraine and sharp price increases for raw materials, energy and logistics subsequently had a highly negative impact on the economic climate, especially in 2022.

The AVK - Industrievereinigung Verstärkte Kunststoffe e.V., Frankfurt/Germany, has published its annual market report on fiber-reinforced plastics/composites.

According to the latest figures from the JEC Group, Paris/France, the volume of the global composites market in 2022 totaled 12.7 million tons. Compared with 2021, when the volume was 12.1 million tons, this was an increase of around 5%. By comparison, European composites production in 2022 declined by 6.1%. The overall European composites market thus went down from 2.96 million t in 2021 to 2.78 million tons.

Europe’s share of the world market was therefore around 22 %. America’s market share was on a similar scale. Asia’s global market share, on the other hand, was as high as 50%.

As in previous years, however, developments within Europe were not homogeneous. This is due to highly diverse regional core markets, substantial variability of the materials used, a broad spectrum of different manufacturing processes and widely differing areas of application. Accordingly, different developments can be seen both regionally and, above all, with regard to different processes – although, in 2022, a decline could be observed in all regions and for nearly all processes. The only materials that saw growth were continuous fiber-reinforced thermoplastics (CFRTP) and carbon fiber-reinforced plastics (CRP).

In terms of volume, the largest part of all composite production flowed into the transport sector, which continued to account for more than 50% of the market volume. The next 2 largest sectors were construction and infrastructure, on the one hand, and electrical and electronics, on the other.

According to the latest figures from the JEC Group, Paris/France, the volume of the global composites market in 2022 totaled 12.7 million tons. Compared with 2021, when the volume was 12.1 million tons, this was an increase of around 5%. By comparison, European composites production in 2022 declined by 6.1%. The overall European composites market thus went down from 2.96 million t in 2021 to 2.78 million tons.

Europe’s share of the world market was therefore around 22 %. America’s market share was on a similar scale. Asia’s global market share, on the other hand, was as high as 50%.

As in previous years, however, developments within Europe were not homogeneous. This is due to highly diverse regional core markets, substantial variability of the materials used, a broad spectrum of different manufacturing processes and widely differing areas of application. Accordingly, different developments can be seen both regionally and, above all, with regard to different processes – although, in 2022, a decline could be observed in all regions and for nearly all processes. The only materials that saw growth were continuous fiber-reinforced thermoplastics (CFRTP) and carbon fiber-reinforced plastics (CRP).

In terms of volume, the largest part of all composite production flowed into the transport sector, which continued to account for more than 50% of the market volume. The next 2 largest sectors were construction and infrastructure, on the one hand, and electrical and electronics, on the other.

Regional market developments

The underlying data covers all long and continuous fiber-reinforced thermoset materials. Thermoplastics are not included in the regional analysis, as there is currently no regional breakdown of these quantities of materials. The percentage distribution by regional core areas has hardly changed at all between 2021 and 2022. The German thermoset market reached a volume of 222,000 tons in 2022. As in previous surveys, Germany was the largest market in the regions covered, representing 19.5% of the total.

Second place was taken by the Eastern European countries with a market share of 18.8% and a volume of 214,000 tons. Spain and Portugal formed the third largest group, with a processing volume of 166,000 tons and a market share of 14.6%. Italy followed closely behind Spain and Portugal, with a market share of 14.2% and a composites processing volume of 162,000 tons. Taken together, the 4 regions represented two thirds of the European composites market. The second biggest processing region within Europe was the UK and Ireland with a market share of 13.2% and a volume of 150,000 tons. France was a long way behind, with a market share of 10.4% and a production volume of 118,000 tons.

In addition to this purely volume-based perspective, it must always be borne in mind that nearly all regions had very different areas of emphasis in their composites industries. As a result, each country or region was often affected by macro-economic developments in a completely different way. A pan-European view can therefore only ever provide a rough indication of the development.

Other composite materials: CRP and NFRP

In addition to the material groups discussed so far, carbon fiber-reinforced plastics (CRP) and natural fiber-reinforced plastics (NRP) are the most important ones in terms of volume. The CRP market volume developed highly dynamically in 2022, achieving 9.6% growth compared with 2021. The overall volume in Europe rose to 57,000 tons.

No new information is currently available for NRP.

Outlook

How will the composites market develop in the medium and long term? Over the last few years, markets have been changing at an increasingly rapid pace.

The 2 central areas of application for composites are construction and infrastructure, on one hand, and transport, on the other. Both areas also have a major impact on the wider economy, which – due to the interdependencies mentioned above – often develops in parallel. This wider economy has been and is still being shaken by several severe crises. In particular, it has been weakened by the Covid-19 pandemic and other negative factors such as the war in Ukraine – factors which are continuing to cause major potential insecurities.

The manufacturing sector, which includes the production of composite components, has traditionally been more important in Germany than in the other large economies of the EU. This makes Germany’s economy particularly dependent on the industry.

We cannot currently provide any reliable quantitative forecast of the development of production volumes in composites within the various regions and manufacturing sectors. One key indicator for assessing the situation from a manufacturer’s perspective is the Producer Price Index.

A detailed analysis of contributing factors shows that the main driver of the enormous increase has been, above all, a massive rise in energy prices. The strong rise in the cost of production in the most important European national economies seems to have stopped for the time being, and the relevant indicators are currently beginning to come down. However, the resulting price reductions – measured in terms of short-term purchase values on the stock exchanges – might still be significantly lower. The future still holds plenty of potential for price drops.

In addition to manufacturing costs, another extremely important element in the highly internationalized composites market is the cost of logistics. Here, too, some of the costs have fallen sharply. After increasing almost tenfold during 2021, container freight rates have now returned to pre-crisis levels.

Despite the latent danger of a global recession, the above indicators currently suggest that markets are calming down. For example, the GfK Consumer Climate Index, which measures the level of income and consumer confidence for the next 12 months, has edged up a little in recent months, after its historic low in October 2022 (-42.8 points), so that it is now at -30.5 points.

For the composites industry, the 2 most important purchasers are the transport sector and the infrastructure and construction sector. Taken together, these 2 areas account for more than 70% of the market volume. However, developments in these core markets were very different.

A sharp drop in new car and commercial vehicle registrations in 2022 has been mentioned, resulting in the lowest value for 30 years. The construction sector, as the second largest application segment, often proved to be robust during the crisis, although there has been a slight decline in construction activity in recent months.

Another reason for optimism is the employment situation, which also has a significant impact on private consumer spending. In early 2023, the average unemployment rate in the EU was lower than it had been for many years.

Despite the challenges mentioned above, composites are set up for success in the future. There is much to suggest that the fundamentally positive developments of the last few years will continue. In the medium term, structural changes in the transport sector will open up numerous opportunities for composites to gain a new foothold in new applications. Major opportunities can also be seen in construction and infrastructure, an area where composites offer enormous hope due to their unique level of properties that predestine them for long-term use. The main assets of these materials in terms of application are clearly their durability, their almost maintenance-free use, their potential for use in lightweight construction and their frequently positive impact on sustainability.