Asahi Kasei/Microwave Chemical

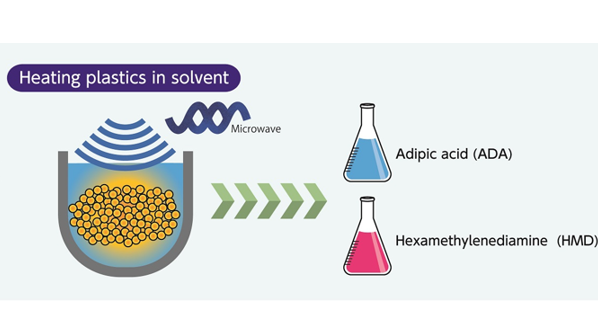

Decomposition of PA 66 with microwave technology (Source: Asahi Kasei)

A joint demonstration project with the objective of commercializing a chemical recycling process for polyamide 66 (PA 66) using microwave technology was launched in April 2023 by Asahi Kasei and Microwave Chemical. The process utilizes microwaves to depolymerize PA 66 and directly obtain the monomers hexamethylenediamine (HMD) and adipic acid (ADA), which is expected to be accomplished at high yield with low energy consumption. The monomers obtained can then be used to manufacture new PA 66.

In the demonstration, scraps from manufacturing and post-use waste material of PA 66 for airbags and automobile parts are depolymerized.

Asahi Kasei Corp., Tokyo/Japan, produces fossil fuel-derived HMD and ADA as intermediates to manufacture Leona PA 66, an engineering plastic featuring outstanding heat resistance and rigidity. PA 66 is used in various applications, including plastic parts for automotive and electronic products, and yarn for airbag fabric, and its demand is expected to increase worldwide.

Microwave Chemical Co., Ltd., Osaka/Japan, is promoting technological and business development to achieve carbon neutrality in the industrial sector focused on process development using microwaves, which can directly and selectively heat target substances with high energy efficiency. For chemical recycling, the company is advancing its proprietary PlaWave technology platform for decomposing plastic using microwaves.

Through development combining Asahi Kasei's experience in manufacturing HMD and ADA with Microwave Chemical's achievements in the industrialization of microwave technology, the 2 companies aim to commercialize a manufacturing process for PA 66 that can reduce GHG emissions compared to the conventional manufacturing process.

Laboratory-scale studies that began in 2021 have confirmed the high-yield depolymerization of PA 66 using microwaves, as well as the principle of the separation and purification process after depolymerization. Bench-scale equipment will now be assembled at Microwave Chemical’s Osaka factory by the end of 2023, and a small-scale demonstration trial using this equipment will be performed in 2024 to collect basic process data for commercialization.

The PlaWave technology platform for decomposing plastic using microwaves can depolymerize PA 66 with low energy and obtain HMD and ADA monomers in high yield. The manufacturing process with this technology is expected to reduce GHG emissions compared to the conventional process, while further reduction of GHG emissions may be achieved by the use of renewable energy for the power required to generate the microwaves.

By verifying the process from depolymerization to separation and purification in an integrated manner, this demonstration project aims to enable resource circulation of PA 66 for further reduction of GHG emissions.

Moving forward, based on the results of the small-scale demonstration trial, a decision on the possibility of commercialization will be made by 2025 following detailed analysis. Concurrently with the small-scale demonstration trial, construction of a business model that involves the entire value chain in the chemical recycling of PA 66 will be advanced, aiming to achieve a circular economy together with stakeholders in the PA 66 value chain.

Asahi Kasei aims to be a global partner for its PA 66 customers by providing solutions for their carbon neutrality initiatives through studies of the practical application of material recycling and chemical recycling as well as trials for the commercialization of PA 66 made using biomass-derived intermediates.

Microwave Chemical is working to increase the scale of equipment and to make PlaWave more generally applicable in order to achieve the practical application of the chemical recycling of polymethyl methacrylate (PMMA), automotive shredder residue (ASR), plastic containers and packaging, flexible polyurethane foam, and more.

In the demonstration, scraps from manufacturing and post-use waste material of PA 66 for airbags and automobile parts are depolymerized.

Asahi Kasei Corp., Tokyo/Japan, produces fossil fuel-derived HMD and ADA as intermediates to manufacture Leona PA 66, an engineering plastic featuring outstanding heat resistance and rigidity. PA 66 is used in various applications, including plastic parts for automotive and electronic products, and yarn for airbag fabric, and its demand is expected to increase worldwide.

Microwave Chemical Co., Ltd., Osaka/Japan, is promoting technological and business development to achieve carbon neutrality in the industrial sector focused on process development using microwaves, which can directly and selectively heat target substances with high energy efficiency. For chemical recycling, the company is advancing its proprietary PlaWave technology platform for decomposing plastic using microwaves.

Through development combining Asahi Kasei's experience in manufacturing HMD and ADA with Microwave Chemical's achievements in the industrialization of microwave technology, the 2 companies aim to commercialize a manufacturing process for PA 66 that can reduce GHG emissions compared to the conventional manufacturing process.

Laboratory-scale studies that began in 2021 have confirmed the high-yield depolymerization of PA 66 using microwaves, as well as the principle of the separation and purification process after depolymerization. Bench-scale equipment will now be assembled at Microwave Chemical’s Osaka factory by the end of 2023, and a small-scale demonstration trial using this equipment will be performed in 2024 to collect basic process data for commercialization.

The PlaWave technology platform for decomposing plastic using microwaves can depolymerize PA 66 with low energy and obtain HMD and ADA monomers in high yield. The manufacturing process with this technology is expected to reduce GHG emissions compared to the conventional process, while further reduction of GHG emissions may be achieved by the use of renewable energy for the power required to generate the microwaves.

By verifying the process from depolymerization to separation and purification in an integrated manner, this demonstration project aims to enable resource circulation of PA 66 for further reduction of GHG emissions.

Moving forward, based on the results of the small-scale demonstration trial, a decision on the possibility of commercialization will be made by 2025 following detailed analysis. Concurrently with the small-scale demonstration trial, construction of a business model that involves the entire value chain in the chemical recycling of PA 66 will be advanced, aiming to achieve a circular economy together with stakeholders in the PA 66 value chain.

Asahi Kasei aims to be a global partner for its PA 66 customers by providing solutions for their carbon neutrality initiatives through studies of the practical application of material recycling and chemical recycling as well as trials for the commercialization of PA 66 made using biomass-derived intermediates.

Microwave Chemical is working to increase the scale of equipment and to make PlaWave more generally applicable in order to achieve the practical application of the chemical recycling of polymethyl methacrylate (PMMA), automotive shredder residue (ASR), plastic containers and packaging, flexible polyurethane foam, and more.

Leona, PlaWave = trademarks